Forced induction has always been the holy grail of performance tuning. By cramming more air into the combustion chamber, engines can burn more fuel and produce more power. For decades, enthusiasts have debated the merits of turbochargers versus superchargers. Today, however, technology is rapidly advancing, and both systems are evolving in ways that dramatically improve throttle response, efficiency, and overall drivability. This article dives deep into how forced induction systems are transforming, why it matters for performance driving, and what enthusiasts should know about the latest innovations.

A Brief History of Forced Induction

The concept of forced induction dates back to the early 1900s. Aircraft engines in World War I were among the first to benefit from superchargers, allowing planes to perform at higher altitudes. By the 1960s and 70s, performance cars like the Porsche 911 Turbo and various American muscle cars introduced turbos and blowers into mainstream automotive culture. The early systems, however, came with significant drawbacks: lag, heat, reliability issues, and excessive fuel consumption.

Fast forward to the 21st century, and technology has caught up with ambition. Turbochargers and superchargers are now standard in performance vehicles and even in everyday sedans and SUVs, thanks to downsizing trends and efficiency regulations. But what really excites enthusiasts is how these technologies are becoming sharper, faster, and more reliable than ever before.

Turbocharger Evolution

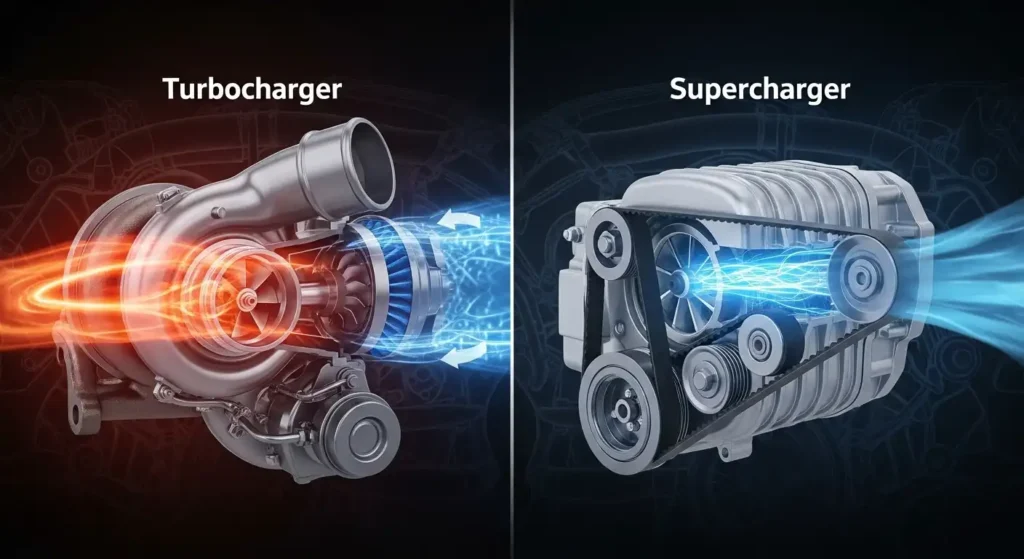

Turbochargers have traditionally been criticized for “lag”—the delay between pressing the accelerator and feeling the power surge. Engineers have made enormous strides to reduce this problem. Let’s look at the innovations:

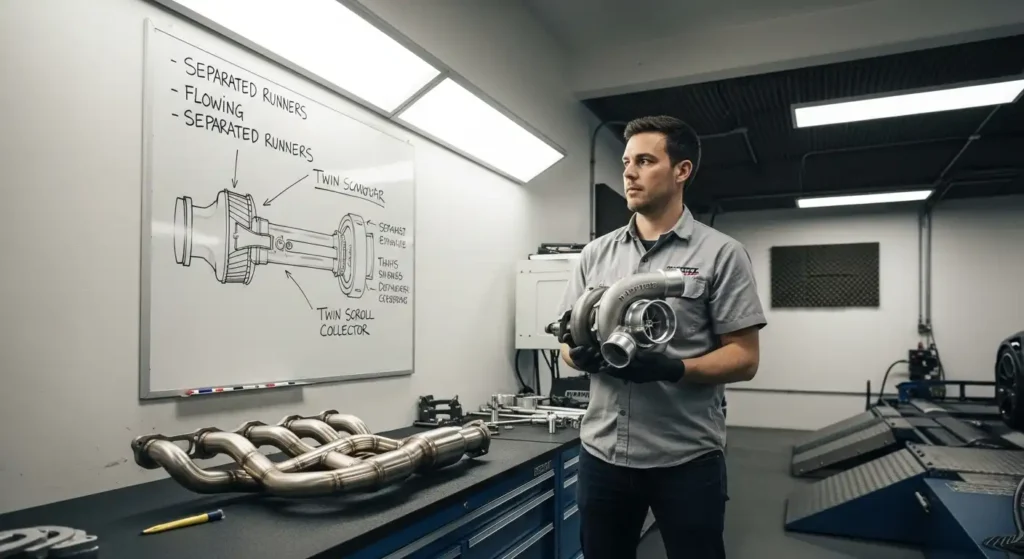

Twin-Scroll Turbos

Twin-scroll designs separate exhaust pulses from different cylinders, reducing interference and improving spool-up times. This results in quicker throttle response and better efficiency across the rev range.

Variable Geometry Turbochargers (VGT)

VGTs use movable vanes inside the turbo housing to adjust airflow dynamically. At low RPMs, the vanes narrow the exhaust path to spool the turbo faster; at high RPMs, they open to prevent back pressure. The result is near-instantaneous response and a wide, usable power band.

Electric-Assisted Turbos

Electric-Assisted Turbos

One of the biggest revolutions is the addition of small electric motors to help spin the compressor wheel. This essentially eliminates lag, as the turbo can be pre-spooled even before exhaust gases build pressure. Mercedes-AMG and Audi are pioneering this technology in production cars.

Improved Materials and Bearings

Modern turbos use lightweight materials such as titanium-aluminide and advanced ceramic ball bearings. These reduce rotational mass and friction, allowing the turbo to spin faster, spool quicker, and last longer under extreme conditions.

Supercharger Evolution

Supercharger Evolution

Superchargers, on the other hand, have always been praised for their instant throttle response, as they are mechanically driven by the crankshaft. Their downside has traditionally been parasitic drag—robbing power to create power. Modern supercharger tech addresses these concerns:

Twin-Screw & Roots Improvements

Twin-screw superchargers provide higher efficiency compared to traditional Roots blowers, compressing air more effectively with less heat. Modern designs also incorporate better intercooling and tighter tolerances to improve efficiency.

Centrifugal Superchargers

These function similarly to turbos but are belt-driven. Advances in compressor wheel design and step-up gearing have improved their efficiency dramatically, offering strong high-end power without excessive lag.

Hybrid Systems

Manufacturers are experimenting with hybrid setups that combine turbochargers with superchargers, offering instant low-end torque from the blower and high-end power from the turbo. Volkswagen’s 1.4 TSI engine and Volvo’s twin-charged engines are prime examples.

Magnetic Clutches

Some modern superchargers now feature electronically controlled clutches, allowing them to disengage when not needed, reducing parasitic losses and improving fuel efficiency.

The Role of Electronics in Forced Induction

Perhaps the biggest leap forward has been in electronic control. Engine control units (ECUs) now use complex algorithms to manage boost, timing, and fueling with surgical precision. Drive-by-wire throttle systems allow smoother transitions, while knock sensors and real-time air-fuel monitoring keep engines safe at higher pressures. Tuning software has also exploded in capability, giving enthusiasts more flexibility than ever before.

Cooling & Heat Management

Heat has always been the Achilles’ heel of forced induction. Advances in intercooler design, water injection systems, and thermal coatings are helping manage intake air temperatures. Air-to-water intercoolers, for example, offer more consistent cooling, while high-performance radiators and oil coolers keep engines reliable under track conditions.

Forced Induction in Electric & Hybrid Cars

Interestingly, the future of forced induction may involve electrification. While pure EVs don’t need turbos or superchargers, hybrid systems can still benefit from forced induction for their combustion engines. Additionally, electric superchargers are gaining popularity as range extenders and power boosters.

Practical Benefits for Enthusiasts

Practical Benefits for Enthusiasts

So what does this mean for the average enthusiast? In short, better drivability. Modern turbos spool almost instantly, and superchargers no longer drain as much power. This makes forced induction cars not only faster but also more enjoyable on daily commutes and more reliable for track use.

Tuning Considerations

With new technology comes new responsibility. Tuning a variable-geometry turbo or an electronically clutched supercharger is more complex than older setups. Proper calibration is critical, and cheap or poorly executed tunes can quickly lead to engine failure. Enthusiasts should work with reputable tuners who understand the intricacies of these advanced systems.

Forced Induction in Motorsports

Forced Induction in Motorsports

From Formula 1 to World Rally, forced induction remains at the forefront of motorsports. The latest generation of race cars uses hybrid turbocharging systems that combine electric motors with exhaust-driven turbines, offering both performance and energy recovery. Lessons from racing often trickle down to street cars, meaning what’s cutting edge on the track today could be in your driveway tomorrow.

Looking Ahead

The future of forced induction is exciting. With electrification, materials science, and software all advancing rapidly, we can expect even more responsive, efficient, and durable systems. Whether you’re a purist who loves the scream of a blower or a turbo addict chasing boost, the next decade promises thrilling developments.

Supercharger Evolution

Supercharger Evolution

Practical Benefits for Enthusiasts

Practical Benefits for Enthusiasts Forced Induction in Motorsports

Forced Induction in Motorsports